Have you ever found yourself with a rubber o-ring that just seems a bit too big for its spot? Maybe it stretched out, or perhaps you just have one that needs to be a little smaller. It happens more often than you might think, actually, when you are working on different projects around the house or with your vehicle. Getting a seal that fits just right is pretty important, and a stretched o-ring can cause all sorts of little leaks or issues that you really don't want to deal with, you know?

When an o-ring gets bigger than it should be, it stops doing its job properly, and that can be a real headache. Instead of throwing it away and trying to find a new one, which can sometimes be a bit of a challenge, there are ways to bring it back to its proper size. We're talking about making it pull in a bit, so it can once again create that snug seal it was meant to provide. It's about getting things to fit as they ought to, you see.

This guide will walk you through some practical ways to make those rubber rings smaller, helping you fix things without too much fuss. We will look at methods involving warmth and also some chemical approaches, so you can pick the one that seems best for your particular situation. It's about finding a good fix, more or less, for those times when a rubber piece has grown a little too much.

Table of Contents

- Why Do O-Rings Get Bigger Anyway?

- Understanding How to Shrink Rubber O-Rings with Heat

- Is Chemical Shrinking an Option for Rubber O-Rings?

- Important Safety Pointers for Shrinking Rubber O-Rings

- After Shrinking - What's Next for Your O-Ring?

Why Do O-Rings Get Bigger Anyway?

It's a pretty common question, really, why these little rubber circles sometimes stretch out. You might think they would just stay the same size forever, but that's not always how it goes. Sometimes, if a rubber o-ring is exposed to certain chemicals, like a carb spray that might have gotten on a bowl gasket, it can cause the material to puff up, you know? This is a bit like when a sponge soaks up water and expands.

Other times, just plain old time and being under a bit of pressure can make them change shape. For instance, a fuel pump seal from an older car, like a 78 Datsun 280Z, might just get bigger from sitting around for many years. That's just how some materials react over time, especially when they are left alone and not doing their sealing job. So, it's not always about something going wrong; sometimes it's just the natural way things behave, in a way.

Also, if a rubber piece is put under too much pulling or stretching, it can get longer and thinner, and then it might not go back to its original shape. This is why it's good to know how to shrink rubber o-rings, because you can often fix these kinds of issues rather than needing to get a brand new part. It's a handy skill to have, especially if you find yourself needing to restore something that's seen better days, or has just gotten a bit out of shape.

Understanding How to Shrink Rubber O-Rings with Heat

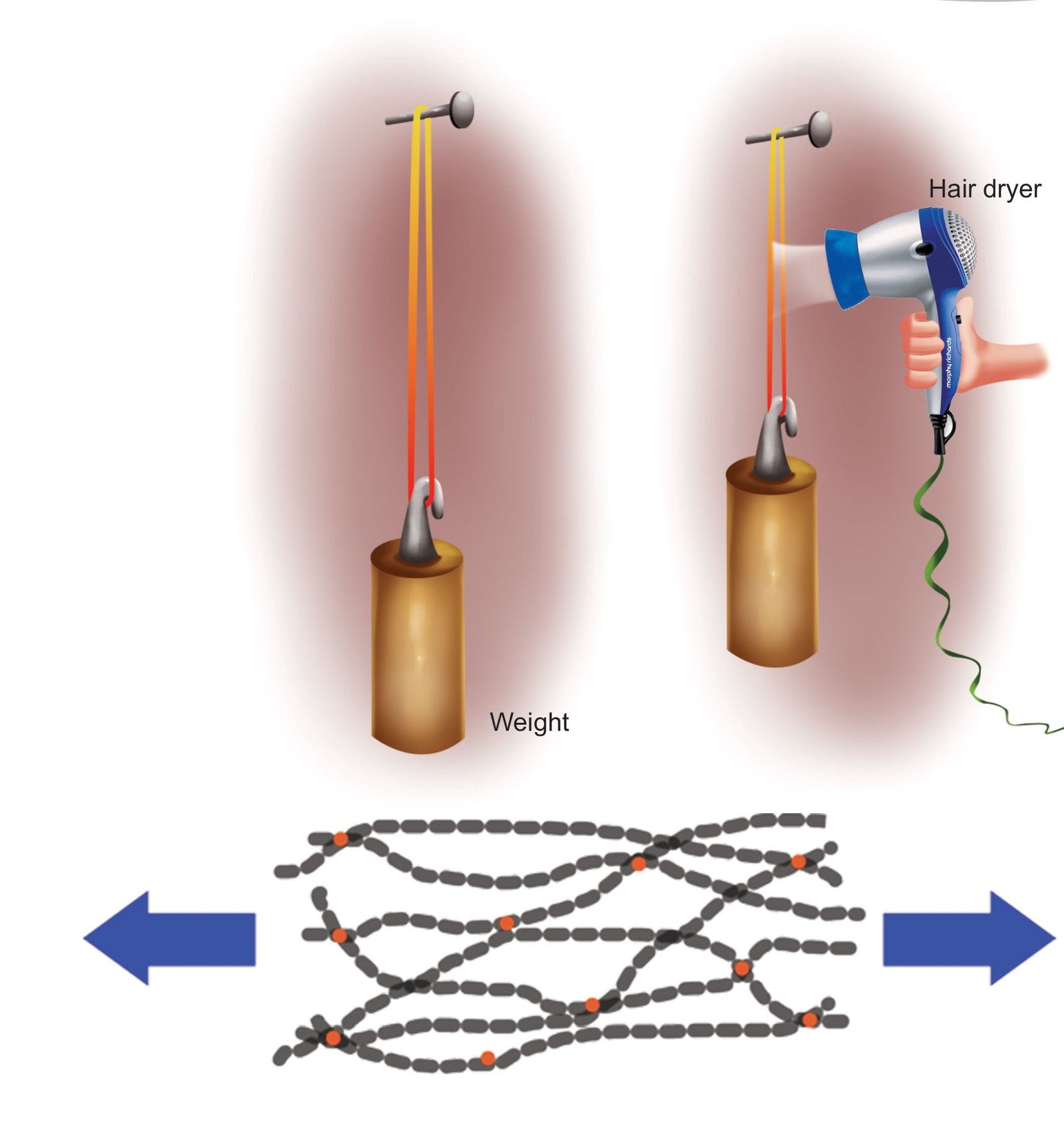

When you want to make rubber smaller, heat is often your first thought, and for good reason. Rubber materials, you see, have a tendency to pull in when they get warm enough. It's like their tiny parts get all excited and want to get closer together, making the whole thing draw up a bit. This is a pretty straightforward way to try and get those stretched o-rings back to a more fitting size, and it's something many people have had good luck with, you know?

There are a couple of main ways to use warmth to help with how to shrink rubber o-rings. You can put them in hot water, which is a gentle and pretty even way to get them warm all over. Or, if you need something a bit more direct, a heat gun or even a hair dryer can do the trick. The key thing is to get the rubber warm enough for a short period, so it starts to pull itself back into shape. It's a pretty simple idea, really, and often quite effective for getting a rubber piece to become smaller.

How to Shrink Rubber O-Rings Using Boiling Water?

Using hot water is probably one of the simplest ways to try and make a rubber o-ring smaller. It's a method that many folks turn to first, and it's pretty easy to do right in your kitchen, you know? If your tap water isn't quite hot enough to do the job, then getting a pot of water to a rolling boil is your next step. The very high warmth from the boiling water really encourages the rubber to pull itself in.

What you do is, you carefully place the rubber o-ring into the boiling water. You'll want to let it stay there for about five to ten minutes. This amount of time usually gives the heat a chance to really work its way into the rubber and make it contract. It's like the rubber gets a little shock from the warmth and decides to get a bit smaller, more or less. Just be sure to watch it, so it doesn't get too warm or stay in there for too long, as that could cause other issues.

After the time is up, you take the o-ring out of the hot water. It should feel a bit firmer and look a little smaller. You can then let it cool down naturally. This method, honestly, is often quite good for bringing those stretched-out seals back to a usable state, especially if you are in a situation where you really need to fix something and don't have a new part readily available. It's a practical way to how to shrink rubber o-rings, for sure.

What About Using a Heat Gun or Hair Dryer for Shrinking Rubber O-Rings?

If you're looking for a different way to use warmth, a heat gun or even a hair dryer can be quite useful for making rubber materials, like those o-rings or even rubber gloves, a bit smaller. These tools let you direct the warmth right where you need it, which can be pretty handy for certain items. It's a more targeted approach than a pot of boiling water, you know, and sometimes that's what you need for a quick fix.

When you use a heat gun or a hair dryer, you want to move the tool around constantly, so the warmth spreads out evenly and doesn't just sit in one spot. Holding it still in one place could make the rubber too hot too quickly, and you don't want to melt it or cause it to get damaged. You are just trying to encourage the rubber to pull in a little, not to turn it into a puddle. So, keep it moving, like you're painting with warmth, more or less.

The amount of time you need to apply the warmth will depend on how much the rubber has stretched and how much you want it to shrink. It's a bit of a trial and error thing, so you might need to do it in short bursts and check the o-ring's size as you go. This method is pretty effective for how to shrink rubber o-rings when you need a bit more control over the warmth, and it can often get the job done without too much fuss, you know?

Is Chemical Shrinking an Option for Rubber O-Rings?

Sometimes, warmth just isn't the right answer, or maybe it doesn't quite get the job done for making your rubber o-rings smaller. That's when you might start thinking about using certain liquids to help the rubber pull in. Yes, some chemicals can actually cause rubber to shrink, which is pretty interesting, you know? It's a different way of going about it, and it depends a lot on the kind of rubber you're dealing with.

To try and make rubber smaller with chemicals, you would typically need a specific kind of liquid that makes the rubber react in that way. Things like acetone or ethanol are sometimes mentioned for this purpose. You also need a container where you can let the rubber soak in the liquid. It's not as simple as just dipping it in, though; the amount it shrinks can depend on the exact type of rubber and how long you let it sit in the chemical. So, it's a bit more involved, in some respects, than just using warmth.

When Should You Consider Chemical Ways to Shrink Rubber O-Rings?

Thinking about using chemicals to make rubber smaller is usually something you consider when other methods, like using warmth, haven't quite worked out, or if you know the rubber material is especially sensitive to warmth. It's a bit more of a specialized approach, and it truly calls for you to be careful and know what you're doing, you know? Not all rubber types react the same way to chemicals, so what works for one might not work for another, or could even damage it.

If you decide to go this route for how to shrink rubber o-rings, you'll need to get your hands on a chemical shrinking agent, like acetone or ethanol. You then place the rubber piece into a container with the liquid, letting it soak for a period. The exact time it needs to soak will depend on the rubber itself and how much you want it to pull in. This kind of shrinking needs a bit of a steady hand and a good eye, because the amount it shrinks really comes down to the specific material and what you want it to do in the end. It's a pretty precise task, in a way.

This method is generally something you'd try if you're in a real bind and have no other choice, or if you're working with a rubber that's known to respond well to chemical shrinking. There are some tutorials out there that talk about fixing stretched rubber rings, and they sometimes put the methods into two main groups: using warmth or using chemicals. So, if warmth doesn't do the trick, this might be your next thought, you know?

Important Safety Pointers for Shrinking Rubber O-Rings

No matter which way you choose to make your rubber o-rings smaller, keeping yourself safe is super important. When you are dealing with warmth, like boiling water or a heat gun, things can get pretty hot, obviously. So, you need to be very careful not to burn yourself. Using kitchen tongs to put the o-ring into hot water and take it out is a good idea, for instance, to keep your hands away from the warmth.

If you're using a heat gun or hair dryer, remember to keep it moving, as I was saying earlier, so you don't overheat one spot and damage the rubber or cause it to get too hot to handle. Also, make sure you're working in a spot where there's good airflow, especially if you're using a heat gun, because some materials can give off fumes when they get very warm. It's just a sensible thing to do, you know?

Now, if you're thinking about using chemicals, safety becomes even more of a big deal. Liquids like acetone or ethanol can be strong, and you really don't want them on your skin or in your eyes. Wearing gloves and eye protection is absolutely a must. Also, work in a spot that has plenty of fresh air, because the fumes from these liquids can be pretty strong and not good to breathe in. It's about being smart and protecting yourself while you're trying to how to shrink rubber o-rings, you know?

And here's a little tip that's pretty useful: when you're putting your o-ring back into place, especially if it's going into a groove, it's a good idea to use a bit of silicone grease. Just put it in the grooves where the o-ring sits, not on the bottom of the ring itself or above it. This helps the o-ring slide into place smoothly and can also help it stay put. It's just a little thing that can make a big difference, honestly, in how well your seal works after all your efforts to make it smaller.

After Shrinking - What's Next for Your O-Ring?

Once you've managed to make your rubber o-ring smaller, the next step is to see if it now fits the way you need it to. You'll want to carefully try putting it back into its spot to check the fit. It should feel snug, but not so tight that it's a struggle to get it in. A good seal is usually one that feels just right, you know, not too loose and not too squished. It's about finding that happy medium, really.

Sometimes, you might find that it's still a little bit off, or maybe you made it a tiny bit too small. That's okay. The degree to which a rubber piece shrinks really depends on how long it was exposed to the warmth or the chemical, and what kind of rubber it is. So, it's not always a one-and-done kind of thing. You might need to try the shrinking process again, but for a shorter period, or perhaps with a bit less warmth, to get it just right.

It's also a good idea to keep an eye on the o-ring after you've put it back into service. Just make sure it's doing its job and not causing any new issues. If it was leaking before, check for any signs of continued leaks. This is especially true for things like fuel pump seals, where a good seal is pretty important for safety and proper function. So, basically, after you figure out how to shrink rubber o-rings, the final step is making sure your fix holds up, which is what you want, right?